BDQ Wavy Shield Belt Conveyor

- Classification:product display

- source:Jiujiang FEIDA Machinery CO. Ltd

- release time:2023-04-22 16:53:56

- Views:7727

BDQ Wavy Shield Belt Conveyor

- Classification:product display

- source:Jiujiang FEIDA Machinery CO. Ltd

- release time:2023-04-22 16:53:56

- Views:7727

Being high effective on transportation with large deferent angle, small working area, upright advance, convenient, repairing,BDQ wavy shield belt conveyor is widely used for steel smelting, mining coal, food supplies, porcelain, chemical industry, electric,building materials etc. it’s the main facility in on concrete mixing, port loading and goods delivery. Expensive installed fee,long periods, low precision, bad rigidity and the belt burst for belt deflective running in the whole transportation will greatly shorten the life and add producing cost of traditional conveyors. Our professionals developed to a new type combined the production experience with foreign advanced technology. Virtue of this kind of conveyor: novel structure, powerful function, convenient installation, long working life, low cost, for these win good graces by designing institute and costumers and got national patent( Patent No.ZL99238134.7).

1. Optimizing of airframe structure and manufacture technics

Traditional conveyor is usually made of channel steel and connected by welding. Skills and installation conditions will influence the overall quality and the precision of equipment. Low precision of installation will bring belt deflection and get a worse belt abrasion that will baffle normal running of the conveyor. Because of the weak rigidity of channel steel, the tailor made truss andauxiliary support must be added to raise to a strong support which lead to the complex structure, long installation period and high enterprise fees for such device.

(Fig 1)1.Baffle 2.Bolt 3.Supporting Pole 4.Dust-proff 5.Connecting Plate

The airframe of new type wavy shield conveyor designs to be web plate structure with whole steel bended (the max bended length:12m). Bolt connection instead of welding. As shown in the figure 1. Frame wallboard 1 includes low place plane bracket, concave arc bracket, incline bracket, protruding arc bracket,are adopted to be whole bended steel plate type, which guarantee the whole steel frame without truss and auxiliary support,thus made a simple and artistic look. And the bores on the left and right baffle are installed by combinatorial boring technique so that we can control the quality within the eligible precision scope. To avoid welding deformation and belt deflection and to extend life of conveyor, the supporting poles are made by milling and combinational boring technique. The frames are connected by connecting plate 5 through bolts that avoid welding deformation,besides, low requirement of installation skills to install quickly. The dustproof plates 4 are also easy to be installed to improve working environment. We are able to reclaim the conveyor to a totally enclosed one for protecting the environment(such as cement,buggy, such device is the best choice of delivery dust materials). It’s also used for the outdoor working to keep sleet from erosion. Comparing with traditional conveyor,this new conveyor is of easily assembly, provide convenience to further maintenance, delivery, reform, shift and improve,what's more,it reduces huge cost.It advances a lot: simple structure, strong rigidity, high precision and easy installation, changing and maintenance of belt.

2. Avoiding belt deflection by adding guide structure.

The fatal weakness of traditional wavy shield belt conveyor is: seriously friction among belt shield and pressing roller, guide roller and conveyor belt leads to breakage and dilaceration of shield and belt after only a short time running that curtailed the working life greatly.While shield bel is rather expensive. Therefore, to solve this problem in fundamental could improve the working efficiency and reduce product cost much. Our professionals analyze these problems and summarize the main reasons: the frame of traditional wavy shield belt conveyor adopts welding structure that the precision of installation is hard to reach, the second reason is unavailability of installing the adjusting roller on conveyor belt for the existence of shield and baffle plate so that the belt is easy to be deflective. The previous way to solve the deflection problems is to use guide roller to adjust the running way of belt. But by this way the swerve roller will rub with at least one of shield that leads to abrasion of shield. Here comes up with a new improvement. As shown of the second drawing. Two vulcanized guide deltoid belt 4 are added on the edge of shield belt, incise one corresponding guide groove on swerve pressing roller 1 to avoid direct touch between shield belt 3 and swerve pressing roller 1 by the inosculating of guide deltoid belt 4 and guide groove. Setting some pressing rollers 5 with guide proof to limit the belt deflection that to avoid the extrusion of conveyor belt and guide roller. It protects the conveyor belt and extends the life of whole conveyor.

(Fig 2 )1.Swerve Pressing Roller 2.Wavy Shield Conveyor Shield Belt 3.Shield Side

4. Guide Deltoid Belt 5.Pressing Roller

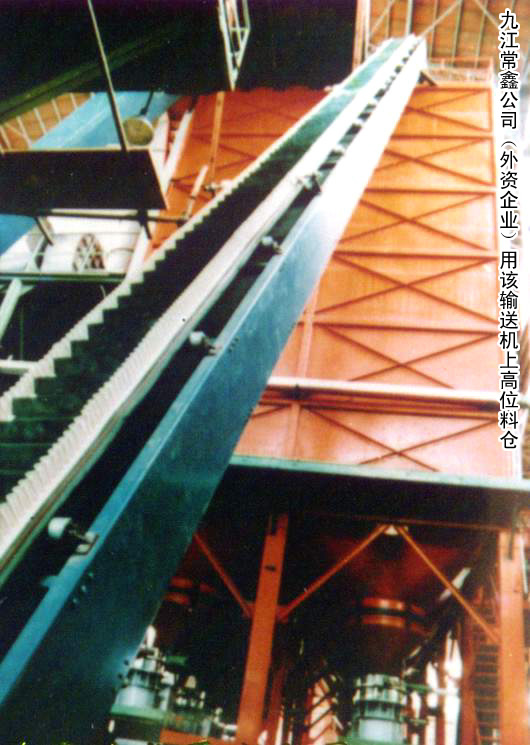

Our new type conveyor—BDQ wavy shield conveyor serves many provinces: Neimenggu, Zhejiang, Guizhou , Guangdong, Jiangxi and Haikou city that have widely applied in the field of electric power, building materials, metallurgy, chemical industry, foodstuff producing. Our new type conveyor is of more scientifical, practicality and economy than traditional one that wins fully affirmation from clients. We hope sincerely to get more advices and criticism from you and craft brothers to devote more for extending market of our products.

| Performance Parameter | |||

| No. | Name | Unit | Scope |

| 1 | Belt Width | mm | 400-1400 |

| 2 | Height of Shield | mm | 40-400 |

| 3 | Board Space | mm | 125-500 |

| 4 | Belt Speed | m/s | 0.4-4 |

| 5 | Obliquity | degree | 30-90 |

| 6 | Theoretical Feeding Volume | m3 /H | 26-1084 |

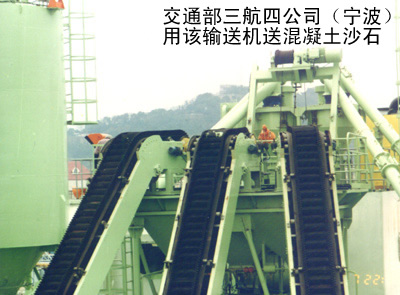

success cases

Scan the QR code and read it with your mobile phone

Jiujiang FEIDA Machinery CO. Ltd

Service Hotline:

company address:

No.16 Shun Xing Road, Ecological Industrial Park, Lushan District, Jiujiang,Jiangxi.P.R. China

Jiujiang FEIDA Machinery CO. Ltd

all rights reserved:Jiujiang FEIDA Machinery CO. Ltd Gan ICP No. 19005654-1